Case studies

Real-world examples of how Helio improves reliability and performance—using thermal simulation (Assess) and optimization (Enhance).

Assess + Enhance working together to improve outcomes.

Case study

Nylon 612

Speed Strength

Assess risk before you run a long job, then enhance speed & quality for iterative airframe parts.

Results

- Printed in Polyamide 612 (Nylon 612) for functional strength

- 30% faster print times

- Faster iteration loops for design changes

- More consistent bonding — even a crash didn’t break layer bonding

Why it matters

- Use Assess as a pre-flight check before committing time + material.

- Use Enhance to reduce 3D print time while maintaining reliability.

- Especially valuable on lightweight geometries where cooling and bonding can vary.

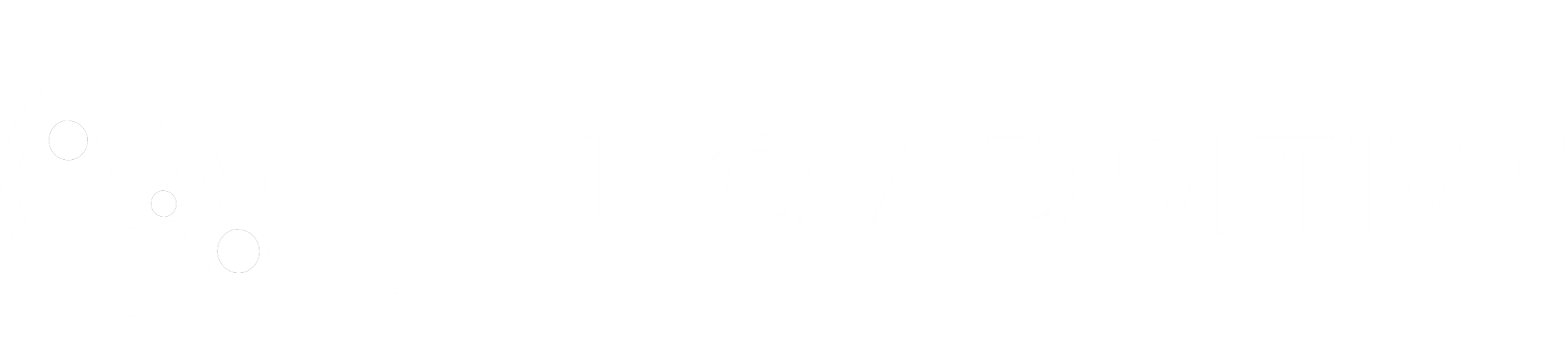

Screenshot

In-slicer Helio screenshot (typically after running Enhance) for this case study.

Printed Part

Photo of the printed part used in this case study.

Case study

Polycarbonate

Speed Strength Deformation

Thermal simulation exposed that default cooling was hurting bonding—then optimization delivered better strength and time.

Results

- +65% tensile strength (30.4 → 50.3 MPa)

- 39% faster 3D print time (1h 43m → 1h 3m)

- Thermal Quality Index: 45% → 93%

Why it matters

- No material or hardware changes — smarter G-code.

- Assess reveals hidden reliability issues (like fan/cooling impacts).

- Enhance tunes layer-time behavior for performance without sacrificing strength.

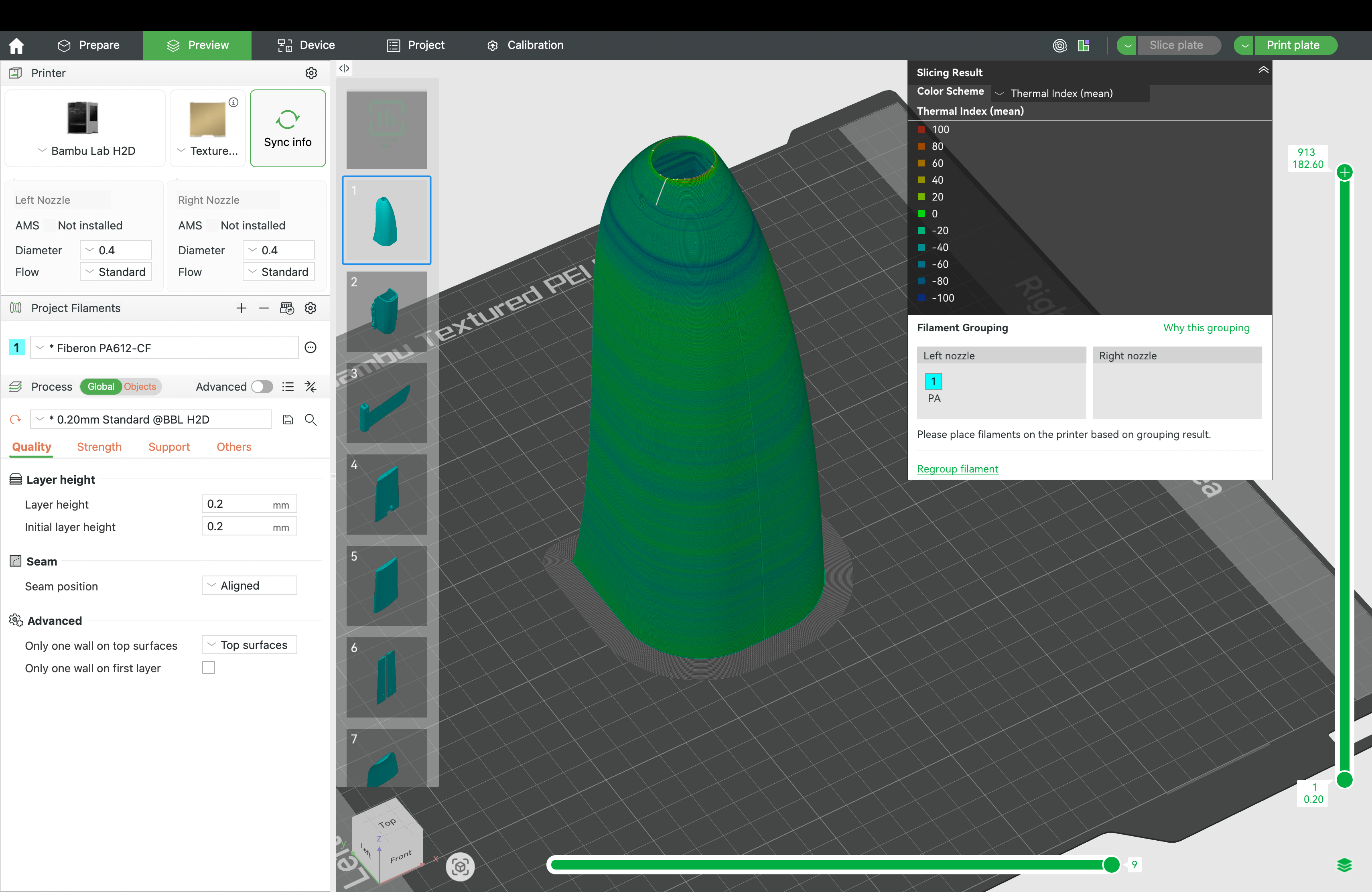

Screenshot

In-slicer Helio screenshot (typically after running Enhance) for this case study.

Printed Part

Photo of the printed part used in this case study.

Case study

Faster PLA

Speed

A controlled test pushed PLA print speed while maintaining surface quality and improving thermal behavior.

Results

- 9% faster 3D print time (6h 36m → 6h 0m)

- Thermal Quality Index improved (-1 → -0.83)

- Surface quality preserved

Why it matters

- Optimization can be limited by cooling strategy; simulation makes that visible.

- Small setting changes can unlock speed without quality loss.

- Assess + Enhance reduces guesswork for common materials.

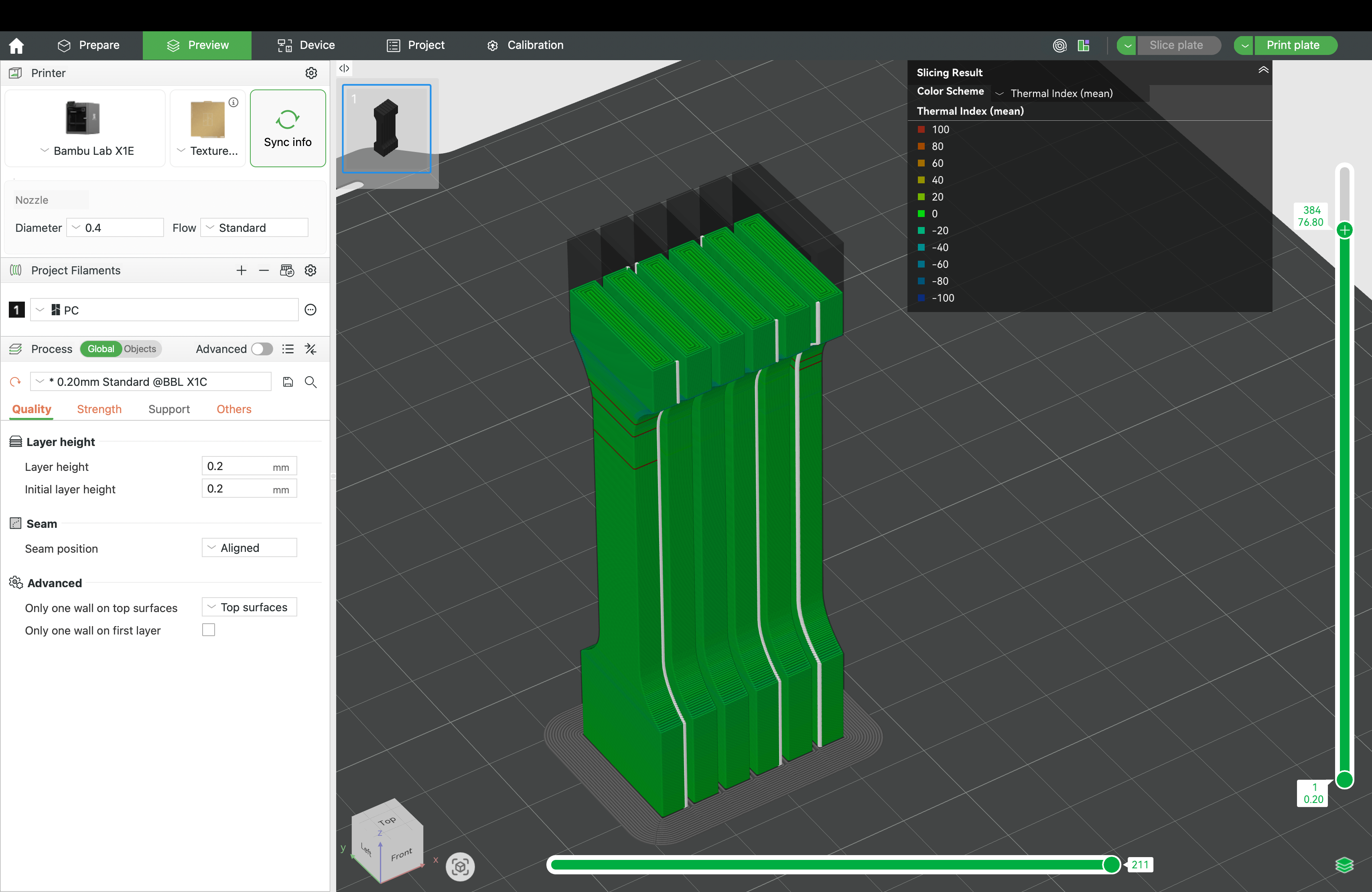

Screenshot

In-slicer Helio screenshot (typically after running Enhance) for this case study.

Printed Part

Photo of the printed part used in this case study.

Case study

PETG-HF

Speed

A functional PETG-HF fixture print pushed speed while maintaining detail—using Helio’s in-slicer thermal simulation and optimization.

Results

- 34% faster 3D print time (1h 5m → 43m)

- TQI improved (-0.15 → -0.13)

- Surface quality and feature detail preserved

Why it matters

- PETG-HF can overheat at high speeds—thermal control keeps layers in the bonding sweet spot.

- Assess makes cooling and risk zones visible before you commit.

- Enhance delivers faster prints with minimal manual tuning while maintaining dimensional intent.

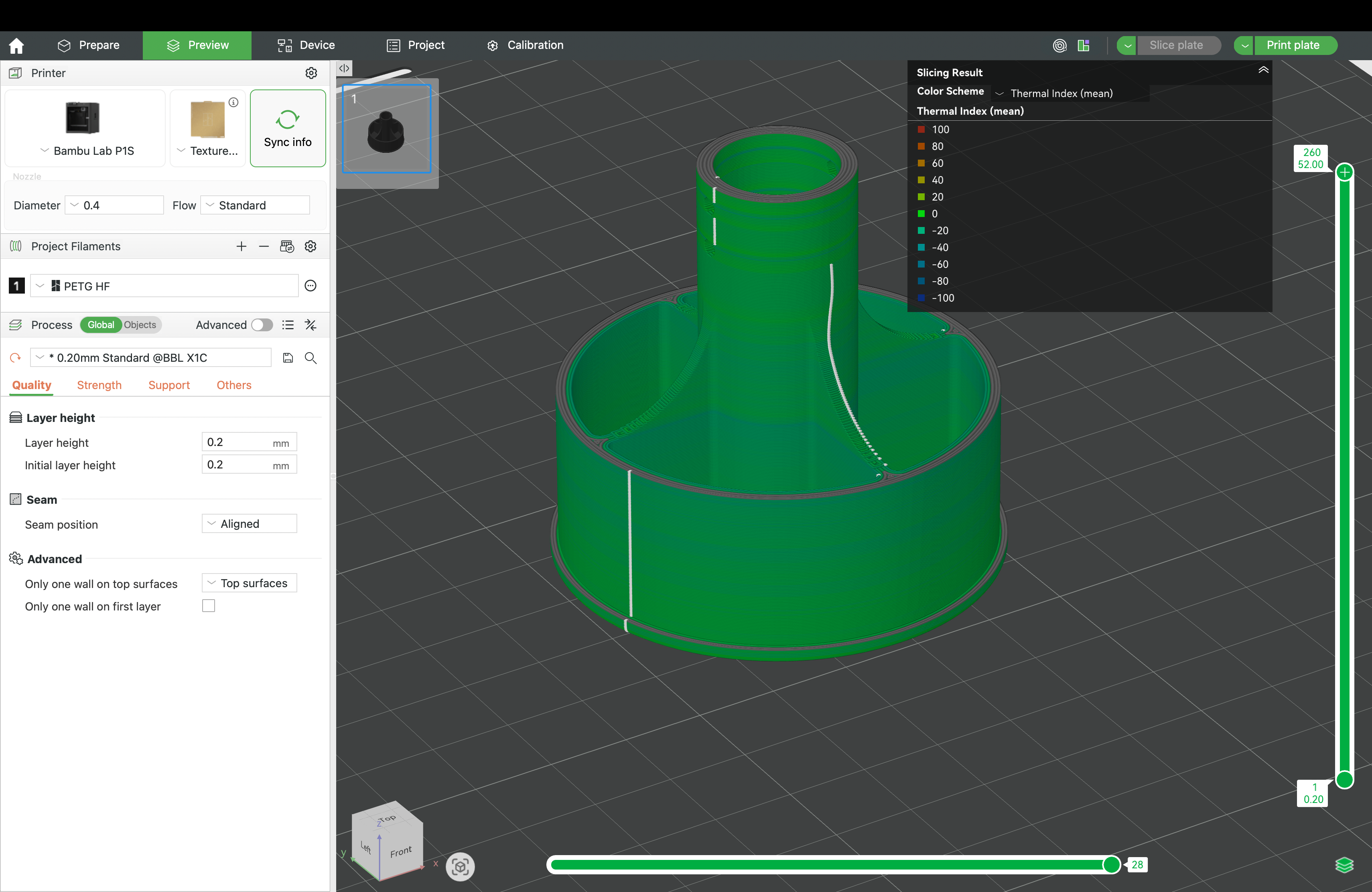

Screenshot

In-slicer Helio screenshot (typically after running Enhance) for this case study.

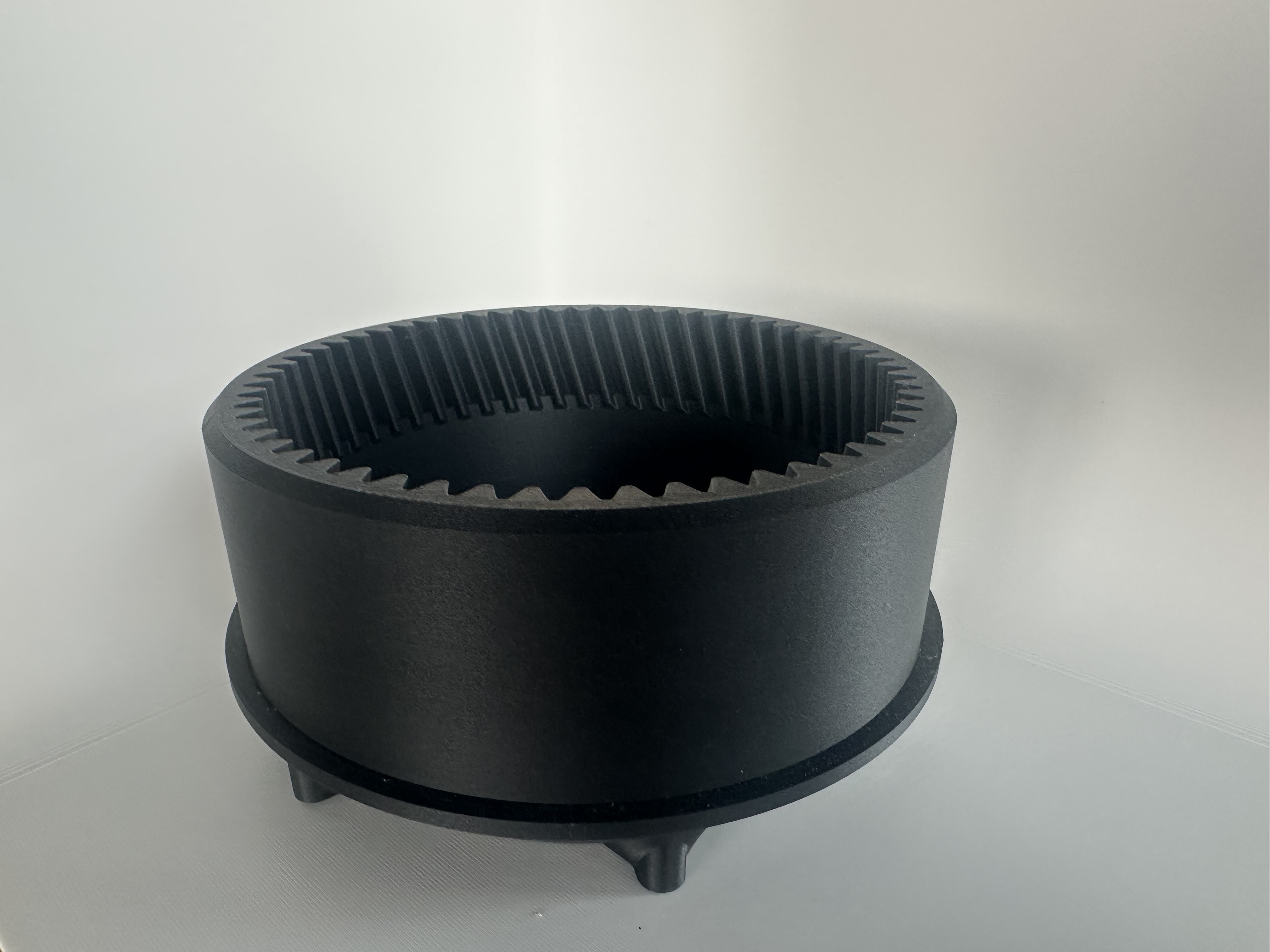

Printed Part

Photo of the printed part used in this case study.

Tip: swipe/scroll horizontally to browse all 4 case studies.