Technology

Helio Additive helps your slicer make better decisions by understanding one thing most print failures have in common: heat. We use a first‑principles, physics-based engine to predict how a part will heat and cool while it prints, then optimize the plan so you can go faster without pushing materials outside their workable range.

Helio does not use AI for these predictions, and we do not train on customer data.

This page is the “how it works” overview for a general audience. If you want the deeper technical details, we link out to the wiki at the bottom.

The big idea: parts remember heat

In FFF/FDM printing, you aren’t placing “cold plastic.” You’re repeatedly heating, depositing, and cooling polymer. That temperature history changes how the material behaves: how well layers fuse, how much it shrinks, and where stresses build up.

Step 1 — A physics model (not guesswork)

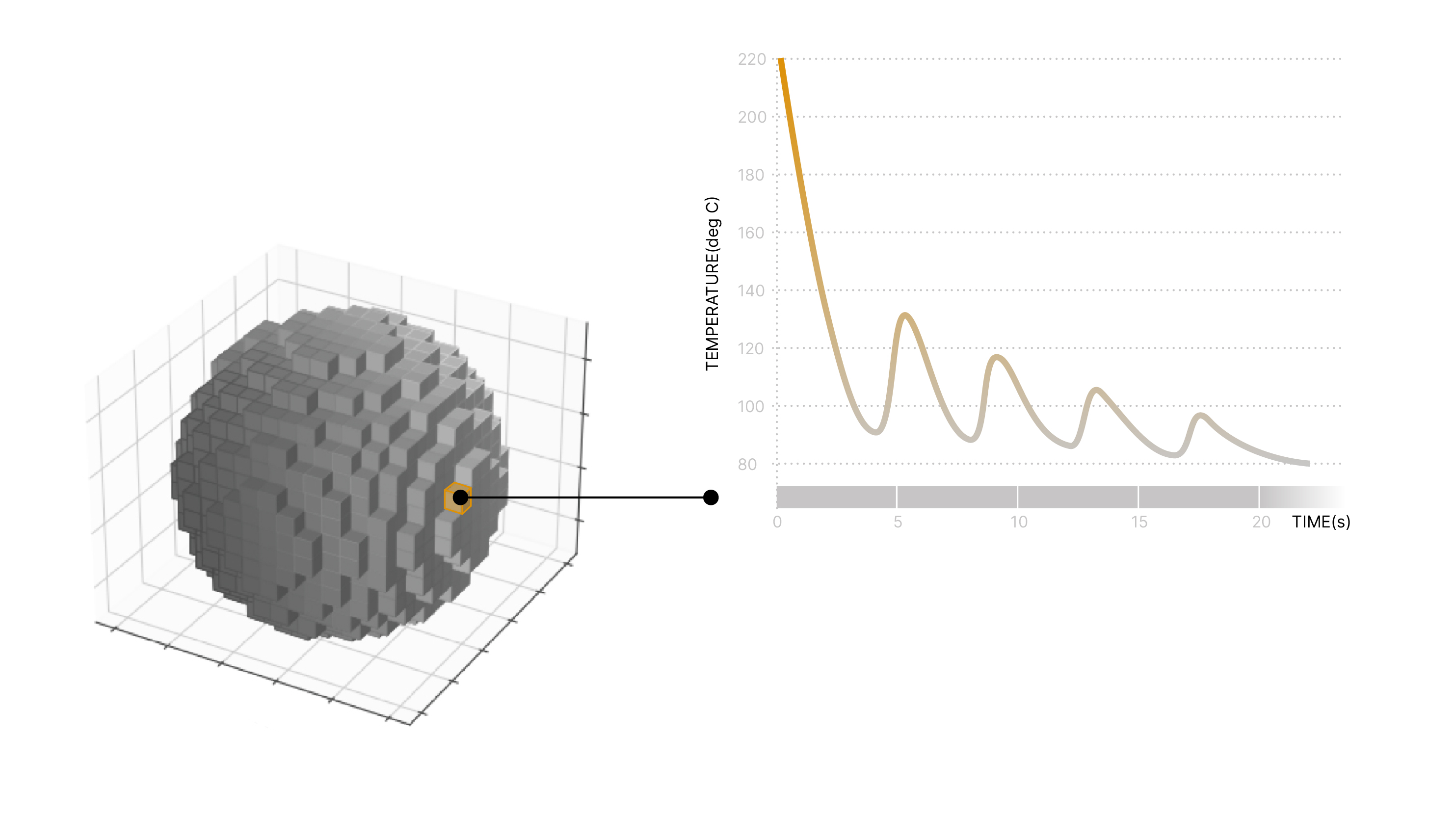

Helio uses a first‑principles, physics-based thermal model to estimate how heat moves through the part as the printer lays down material. You can think of it like a weather forecast for temperature inside your print: not perfect, but grounded in physics and much more reliable than trial-and-error.

- We track how each new line adds heat, and how the part loses heat over time.

- We account for geometry (thin vs thick regions cool differently).

- We identify zones where the process is trending toward over-heating, over-cooling, or uneven cooling.

Step 2 — Simulation turns that into a map of risk

Once we can predict the temperature history, we can flag where the print is likely to struggle: areas that may warp, areas that may not bond well, or areas that are likely to drift dimensionally.

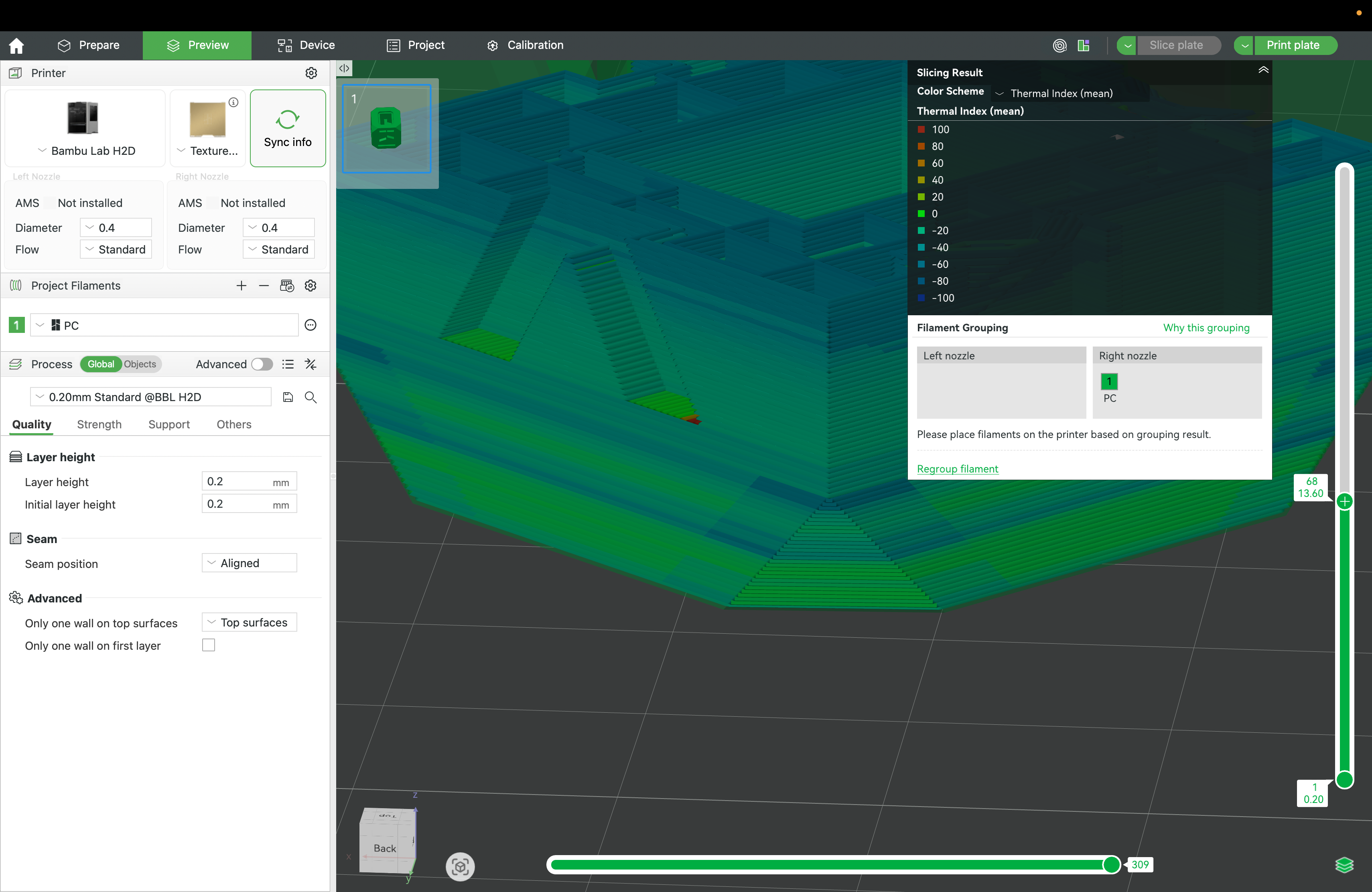

Step 3 — Optimization: go faster without breaking the thermal “rules”

If you only push speed, you often create thermal problems (too hot in some areas, too cold in others). Helio’s optimization searches for print speeds for each road that respects the thermal constraints while still reducing total print time.

- Speed up where the part can safely accept more heat.

- Slow down or add time where cooling/bonding needs it.

- Avoid “ping-ponging” between extremes that cause inconsistency.

What you get in the slicer

The end result is practical: clearer confidence before you print, and a print plan that’s tuned to your part’s thermal reality.